Manufacturing Buckets with IML Labels

Process of Manufacturing Buckets With IML Labels

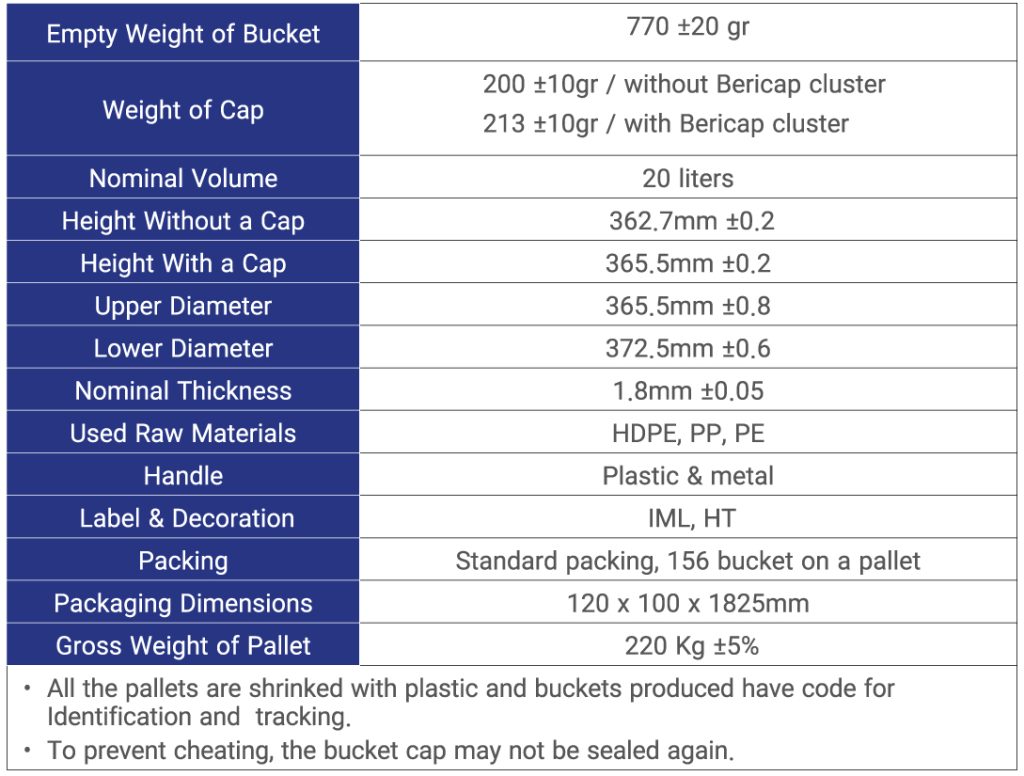

Specifications and Tests of Bucket

General Specifications: It has a smooth, uniform appearance, without pleat and an apparent defect.

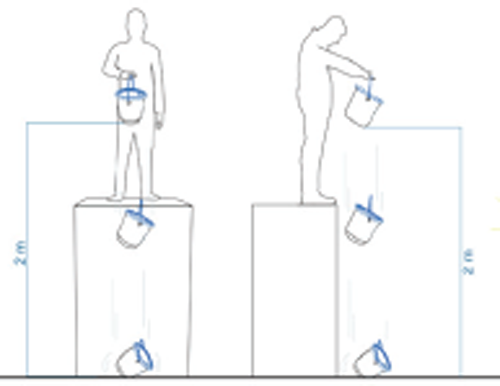

Leak Test: Eighty per cent (80%) of the capacity of the bucket to be filled and placed horizontally four times in four directions and no leakage is observed.

Handle Test for Plastic Handle: It withstands for one hundred (100) times against closing and opening.

Bucket 20 Liters

Bucket 1 Liter

Silicon Cartridge with IML

Hamid Sanat Fard Company in order to present new designed products in the field of sealants and adhesive packaging, research and developed products for silicon cartridge with IML decoration technologies.

Hamid Sanat Fard Company modern and automatic manufacturing lines by using European injection molding machine, molds , robot and expert staff ,able to producing silicon cartridge with high quality that they can compete with European samples.

Using this sophistic and aesthetic packaging, sealant and adhesive manufactures can enter new export markets and satisfied their customers.